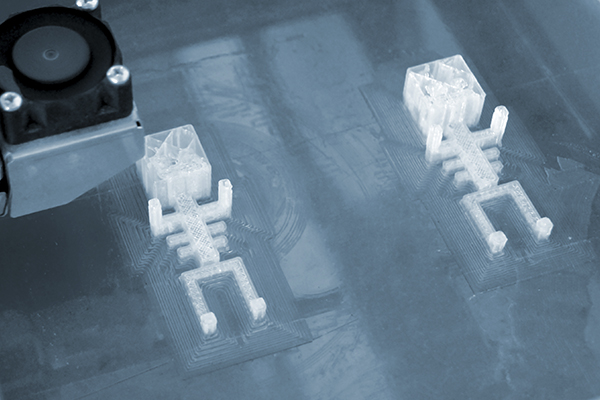

We can easily produce the which are highly needed especially in the medical, chemistry and packaged products fields. Thanks to the prototypes we create, we achieve high quality results in a short time at a lower cost compared to long term production with a high cost.

The most important issue in the production of transparent parts is the post-production processes. Since the product models we work on are transparent, the surface must be clean and clear. The presence of scratches that will affect the appearance is an unacceptable detail. Our professional team, state-of-the-art machinery-equipment and expertise in the working process enable us to prepare 100% transparent parts and offer these to our customers.

Materials used for Transparent Parts;

- Composite

- Photopolymer Resin

- Polyurethane Resin

- PMMA

- Acrylic (Plexi)

- PC

- SAN

- GLASS

Transparent Prototypes are used in

- Glass bottle

- Decorative objects

- Light covers

- Lens

- Medical products

- Ligthing and lamp

- Packaging

- Electronic

- Architectural model fields.